PQ347H eccentric half ball valve

- Product Type : Ball valve

- Introduction : Eccentric hemispherical valve is a new type of industrial valve developed by our company on the basis of introducing and absorbing foreign such valve structure. It can be widely used in medium pressure pipelines such as petroleum, chemical industry, metallurgy, electric power, water supply, etc., and is especially suitable for use in fluid medium pipelines containing impurities and particles.

Product Details

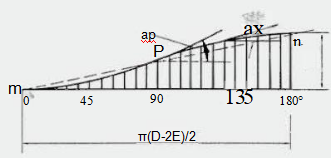

The valve uses a double eccentric structure, the use of eccentric deformation wedge action principle to make the valve seal pair to form a tight and separate. In order to achieve reliable valve sealing and rapid opening and closing.

Performance characteristics

Due to the different radius of rotation of all points on the valve disc sealing spherical surface, the eccentric spherical curve is equal to the curve. When closing, the sealing spherical surface enters the valve seat and closes more and more tightly to form sufficient sealing specific pressure, and the bidirectional sealing performance is stable and reliable.

Because the disc is a full circular straight channel, the flow resistance is small, and it has good flow performance.

The sealing pair has wear resistance, corrosion resistance and long service life.

In the process of switching, the dirt on the sealing surface can be removed without affecting the seal.

In the long-term use, when the sealing position changes, the sealing spherical surface moves forward in equal amount, and still maintains a tight state with the fixed sealing seat, which can realize a new seal.

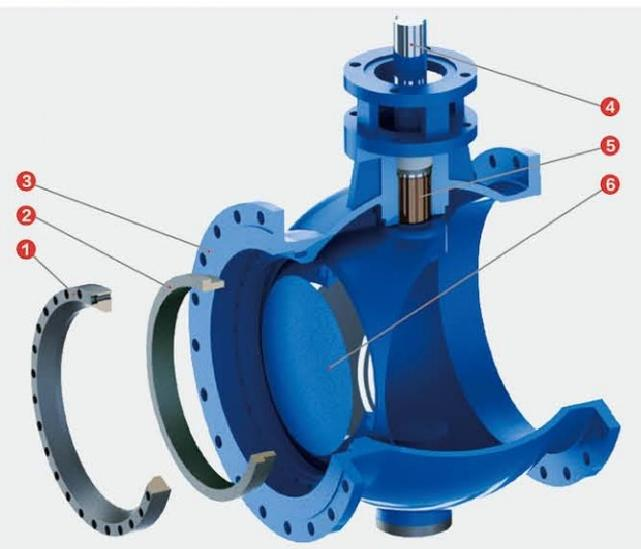

Main parts

|

1 |

Pressure plate |

|

2 |

Hard seal valve seat |

|

3 |

Valve body |

|

4 |

valve shaft |

|

5 |

Self-lubricating bushing |

|

6 |

valve ball |

Executive standards

Design: GB/T 26146-2010 Eccentric ball valve

Flange connection: GB/T9115 (or according to user requirements)

Structure length: GB/T12221-2005 and internal standards

Pressure test: GB/T12221-2008

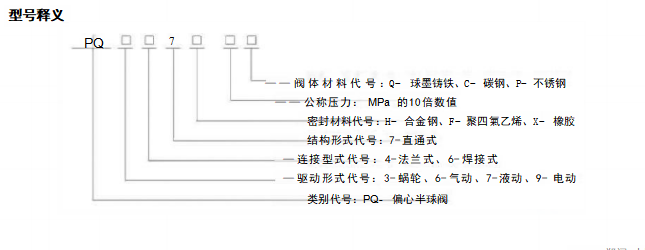

Model Interpretation

|

Name |

Material |

|

Valve body, valve plate |

QT450-10, WCB, stainless steel, alloy steel |

|

valve shaft |

40Cr, stainless steel |

|

Valve Plate Seat |

Alloy carburized steel, nitrided stainless steel, wear-resistant hard alloy |

|

Valve Seat |

Alloy nitriding steel, nitriding stainless steel, wear-resistant hard alloy |

|

Bearing |

aluminum bronze,FZ-1 composite, stainless steel |

|

Packing |

PTFE, flexible graphite |