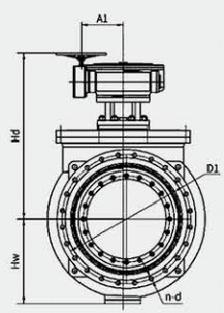

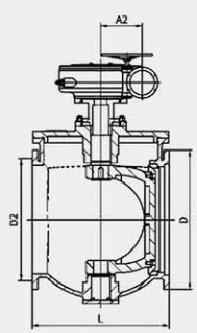

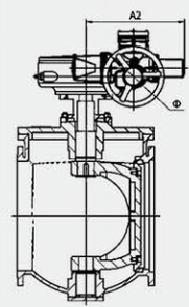

Top-mounted eccentric half ball valve

- Product Type : Ball valve

- Introduction : This series of valves adopt hemispherical top-mounted design, which is convenient for maintenance in use. Without removing the valve from the pipeline, the valve seal can be replaced to complete online maintenance of the valve.

Product Details

Executive standard

Design: GB/T 26146-2010 Eccentric ball valve

Flange connection: GB/T9115 (or according to user requirements)

Structure length: GB/T12221-2005 and internal standards

Pressure test: GB/T13927-2008

Structural features and uses

Small pressure loss: when fully open, the water loss is zero, the flow channel is completely unblocked, and the medium will not deposit in the valve body cavity.

· resistance to particle wear: V-shaped opening of the ball cap and metal valve seat between the shear, in the closing process, only at the last moment of the ball cap to seat, does not form friction, and the seat with wear-resistant nickel alloy, not easy to be scour wear, and thus suitable for containing fiber, small solid particles, pulp and so on.

Suitable for high flow media: straight-through flow channel, strong eccentric crankshaft makes it suitable for high flow rate and no vibration.

Long life: no vulnerable parts, due to the eccentric role, the valve opening and closing when the sealing surface without friction, the service life is long.

· Convenient maintenance: the valve does not need to be removed from the pipeline during maintenance, as long as the valve cover can be opened for maintenance.

Main parts material

|

Valve body |

gray cast iron |

ductile iron |

cast steel |

|

Bonnet |

gray cast iron |

ductile iron |

cast steel |

|

Stem |

2Cr13 |

2Cr3 |

2Cr13 |

|

Valve seat |

Stainless Steel |

Stainless Steel |

Stainless Steel |

|

ball crown |

Ductile iron covered with rubber, stainless steel |

Stainless Steel |

Cast steel covered rubber PF stainless steel |

|

hemisphere |

gray cast iron |

ductile iron |

cast steel |